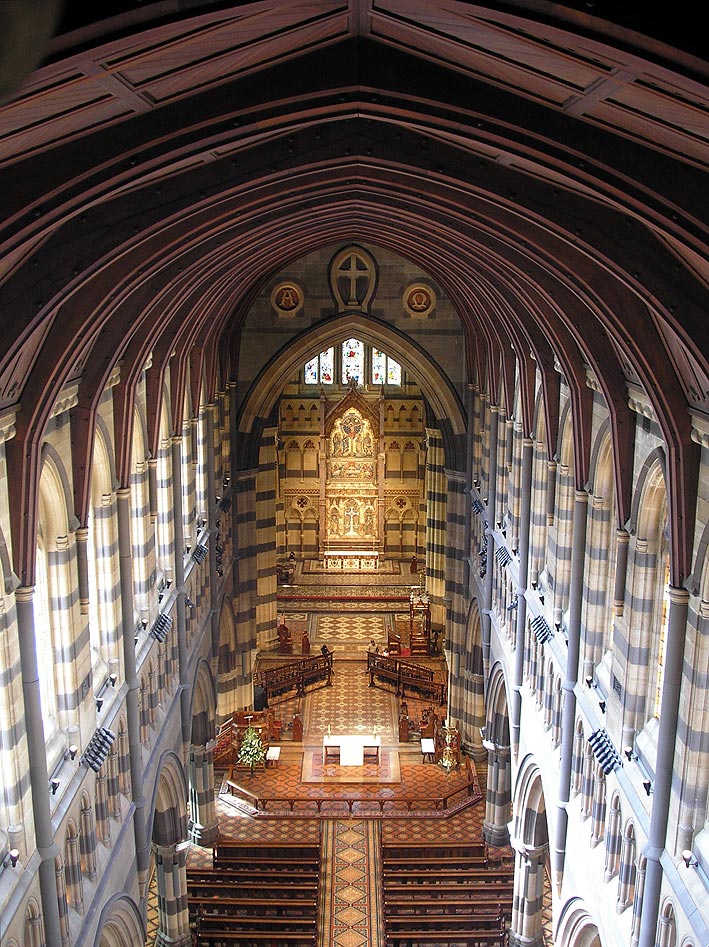

Swanston Street, Melbourne

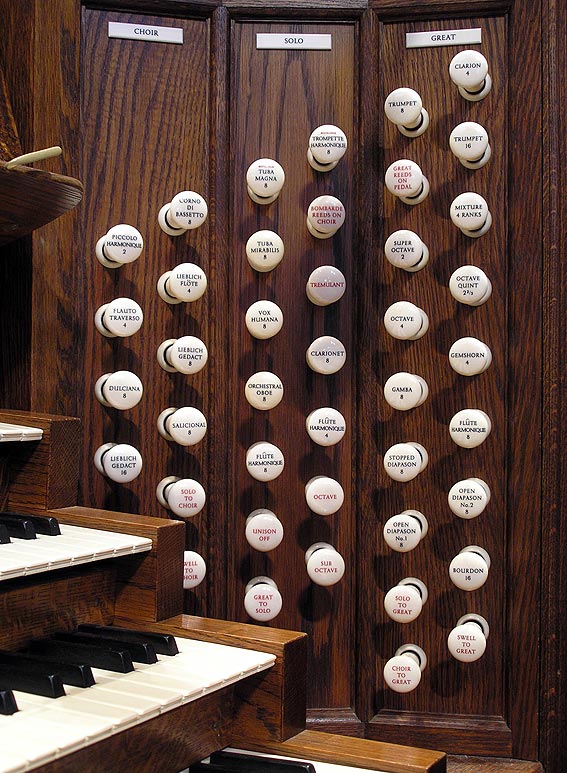

T.C. Lewis, Brixton, London, 1891

4 manuals, 53 speaking stops, el. pn. (orig. tub. pn.)

Restored 1989-1990 Harrison & Harrison, Durham, England

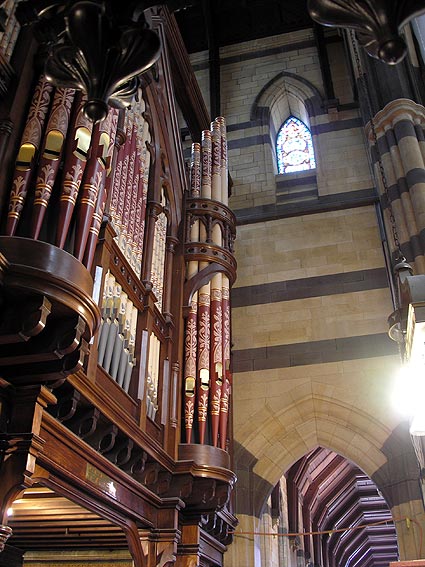

Photo: Simon Colvin (Dec 2007)

The organ at St Paul's Cathedral was built in 1890 by T.C. Lewis, Brixton, London and among the largest productions of this renowned English firm. It was rebuilt in 1929 by Hill, Norman & Beard when the action was electrified and a new console supplied. There was a major restoration in 1989-1990 by Harrison & Harrison Ltd, Durham. The façade pipe stencilling is by Marc Nobel, Christine Holmes and John Dale after a design by Lyon, Cottier, Wells & Company.

Click here to download an MP3 of JS Bach - Sinfonia to Cantata 29 (arr Gehring) - played by David Ratnanayagam on the St Paul's Cathedral organ

SPECIFICATION:

| GREAT ORGAN, 14 stops 1 Bourdon 2 Open Diapason no 1 3 Open Diapason no 2 4 Flute Harmonique 5 Stopped Diapason 6 Gamba 7 Octave 8 Gemshorn 9 Octave Quint 10 Super Octave 11 Mixture 12 Trumpet 13 Trumpet 14 Clarion Great reeds on Pedal Choir to Great Swell to Great Solo to Great SWELL ORGAN, 14 stops 15 Bourdon 16 Geigen Principal 17 Rohr Flöte 18 Viole de Gambe 19 Voix Celestes TC 20 Vox Angelica 21 Octave 22 Rohr Flöte 23 Flautina 24 Mixture tremulant 25 Contra Fagotto 26 Horn 27 Oboe 28 Clarion Solo to Swell sub octave octave CHOIR ORGAN, 8 stops 29 Lieblich Gedact 30 Salicional 31 Lieblich Gedact 32 Dulciana 33 Flauto Traverso 34 Lieblich Flöte 35 Piccolo Harmonique 36 Corno di Bassetto Swell to Choir Solo to Choir SOLO ORGAN, 8 stops Enclosed 37 Flute Harmonique 38 Flute Harmonique 39 Orchestral Oboe 40 Clarionet 41 Vox Humana tremulant 42 Tuba Mirabilis Unenclosed: Bombarde 43 Tuba Magna* 44 Trompette Harmonique* Bombarde reeds on Choir Great to Solo sub octave unison off octave PEDAL ORGAN, 9 stops 45 Open Diapason 46 Great Bass 47 Sub Bass 48 Violone 49 Quint 50 Violoncello 51 Flute Bass 52 Contra Posaune* 53 Posaune Choir to Pedal Great to Pedal Swell to Pedal Solo to Pedal |

16 8 8 8 8 8 4 4 2-2/3 2 IV 16 8 4 16 8 8 8 8 8 4 4 2 III 16 8 8 4 16 8 8 8 8 4 2 8 8 4 8 8 8 8 8 8 32 16 16 16 10-2/3 8 8 32 16 |

Donated by June Nixon and Neville Finney Donated by the Brockhoff Foundation Donated by Sir Ernest Coates |

* 1990 additions

COMPASS Manuals: CC-C 61 notes Pedal: CC-F 30 notes

ACTION electro-pneumatic with solid-state coupling and combination actions

ACCESSORIES

Great and Pedal combinations coupled Pedal to Swell foot pistons

Generals on Swell foot pistons

8 adjustable foot pistons to Pedal

8 adjustable thumb pistons to Swell

6 adjustable thumb pistons to Choir

8 adjustable general thumb pistons

8 adjustable thumb pistons to Great (duplicated by foot pistons)

6 adjustable thumb pistons to Solo

(all of the above adjustable by a solid-state capture system with 8 memories and separate control for general pistons)

5 Reversible foot pistons

12 Reversible thumb pistons

General Cancel thumb piston

Balanced mechanical Swell Pedals to Swell and Solo

WIND PRESSURES

Pedal Open Diapason 32: 2"

Great and Swell fluework, Choir and Pedal Sub Bass, Violone, Quint, Violoncello and Flute Bass: all 3 1/2"

Solo fluework and imitative reeds: 4 1/4"

Swell reeds, Pedal Great Bass, Contra Posaune and Posaune: 5 1/4"

Great reeds: 6" (orginally specified by Lewis as 7"

Solo Tuba Mirabilis, Tuba Magna and Trompette Harmonique: 12"

MIXTURE COMPOSITIONS

Great IV: c - f#' 19.22.26.29, g' - f#1 12.15.19.22, g - C4 5.8.12.15

Swell III: c - c' 15.19.22, c# - c' 8.12.15

The pitch is C = 535 cps @ 60 degrees Fahrenheit, as recorded inside the organ

VOICING was done at Durham by Peter Hopps and Duncan Matthews.

FINAL REGULATION in the Cathedral was done by Peter Hopps and Mark Venning.

CONSULTANTS included,June Nixon, the Revd Howard Hollis, Professor Michael Brimer, John Mallinson, Lindsay O'Neill, John Maidment and Harry Bramma.

Papers on and by TC Lewis from OHTA News:

• John Maidment - T C Lewis

• T C Lewis - A PROTEST AGAINST THE MODERN DEVELOPMENT OF UNMUSICAL TONE

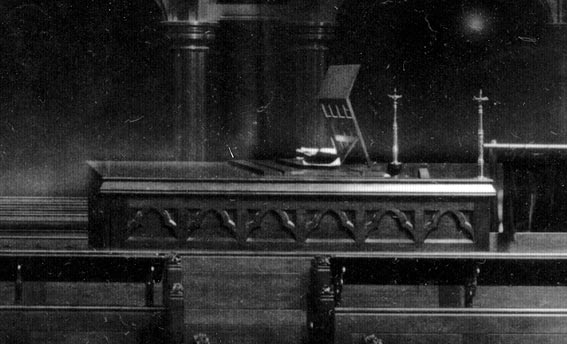

St Paul's console (1890)

from the collection of Dr John Floyd

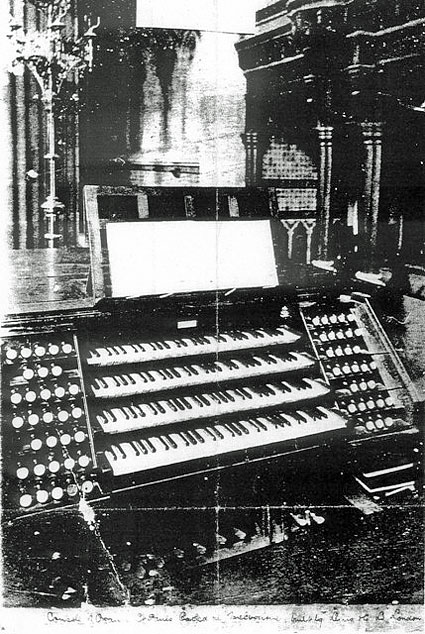

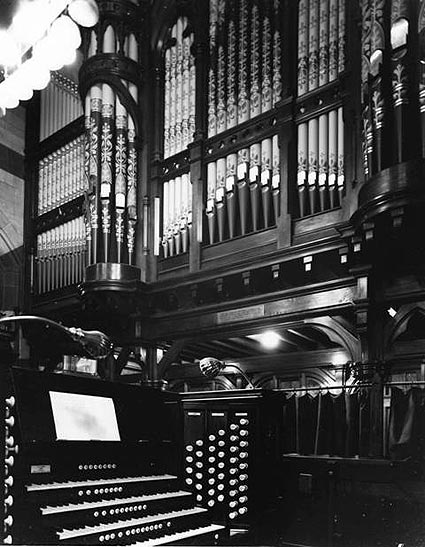

1929 Hill, Norman & Beard console

taken by John L Carey and published in Dr AE Floyd's

Three Voluntaries or Extemporisations [Hinrichsen 1957].

|

|

|

|

|

|

|

|

|

|

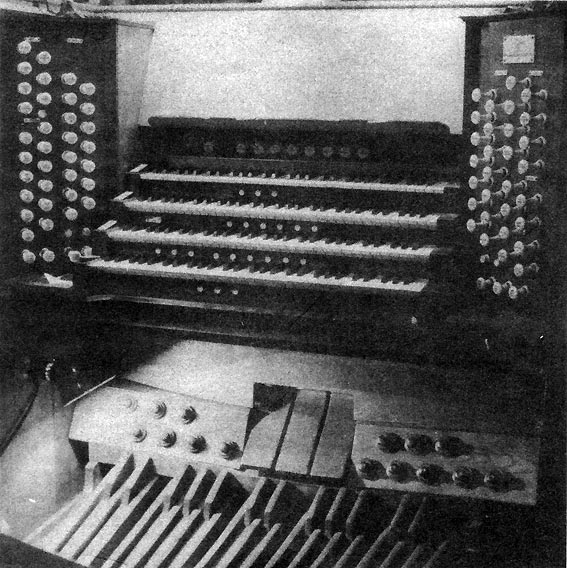

Photos JRM Dec 2006 |

||

|

|

|

|

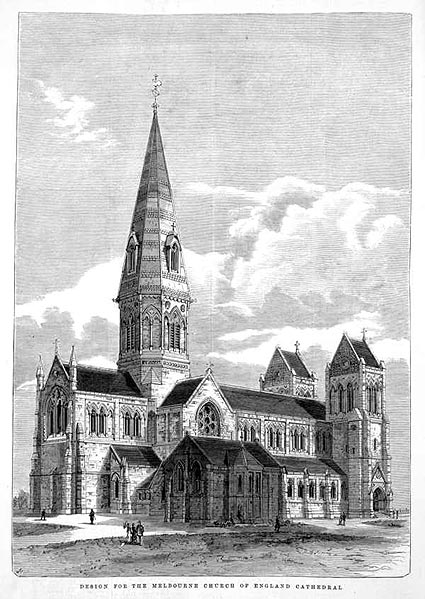

Original Butterfield design |

||

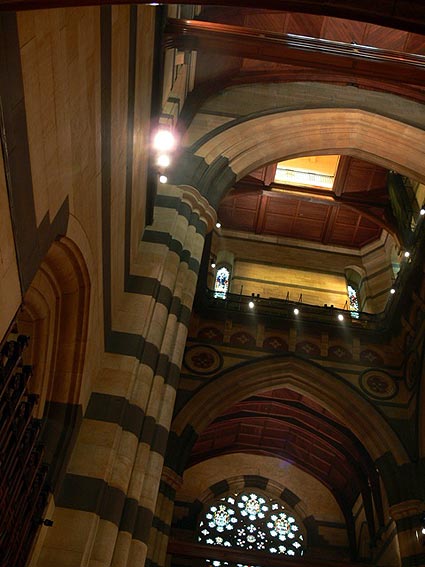

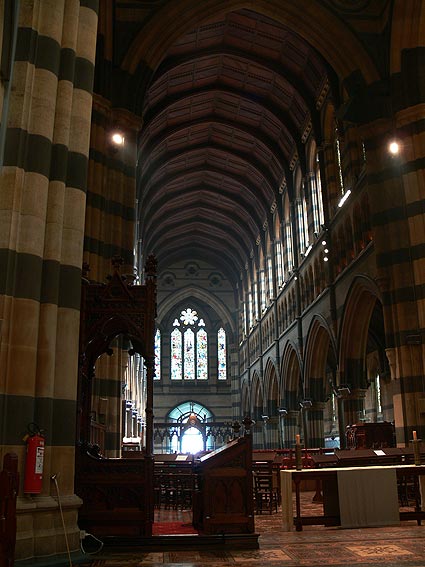

Three photos above: Simon Colvin (Nov. 2007)

|

|

|

|

||

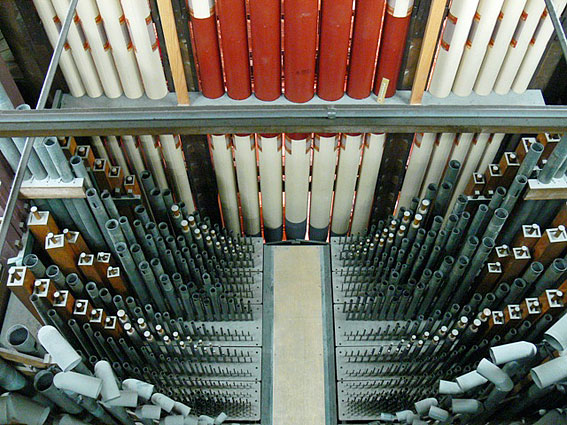

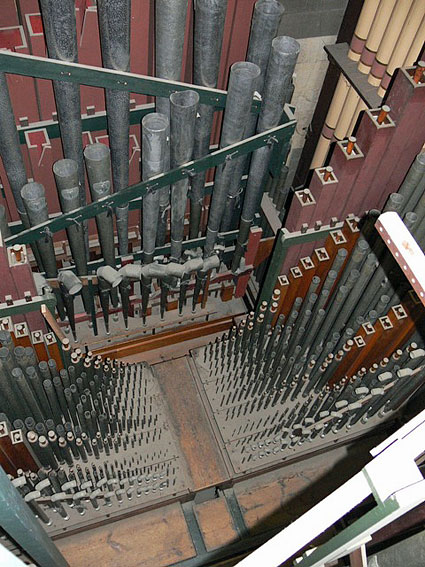

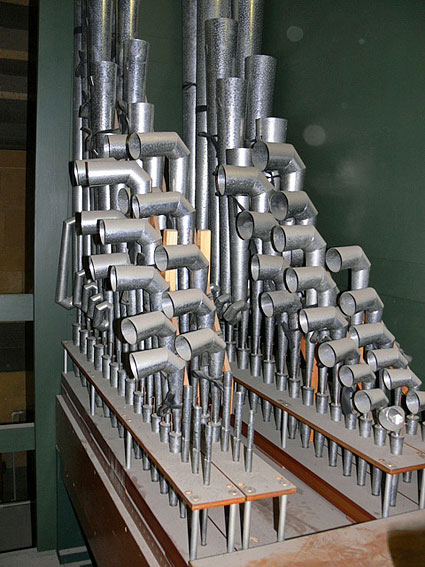

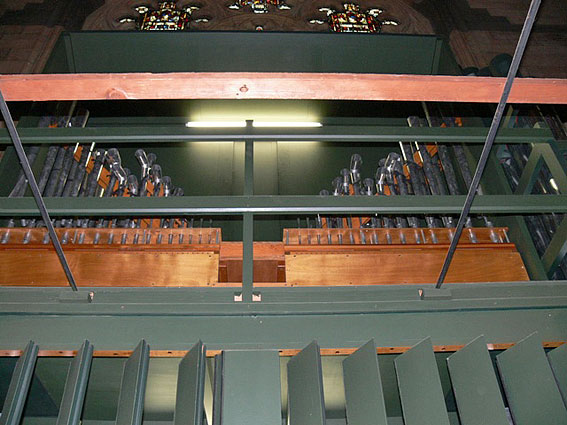

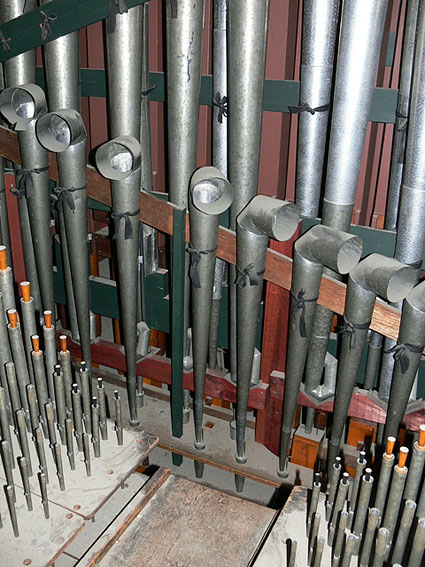

Above: Choir pipework Right: Solo pipework Below left: Great pipework Below right: Swell pipework Photos taken by Brian Hatfield |

|

|

|

|

|

| |

||

|

||

|

||

|

||

|

|

|

Bourdon placed on off-note chests |

||

|

|

|

|

|

|

|

|

|

Contra Posaune 32 to rear |

||

|

||

|

|

|

Orchestral Oboe 8 |

||

|

||

|

||

|

|

|

Great Bass 16, 32 Open Diapason at rear |

||

|

|

|

Flute Bass 8 |

||

|

|

|

|

||

|

||